Easy injection molding

Prototypes and production parts can be machined in as soon as 1 day

Vacuum injection mold, namely vacuum complex mold, also known as silica gel complex mold, needs to be used in silica gel mold. Both under the condition of vacuum deaeration of castable, mixing, preheating, note type, and in constant temperature box 60 ℃, 80 ℃ for 2 to 3 hours of secondary curing process, silicon complex mode of imitation, to reach the strength and hardness of the raw materials such as ABS, can also according to customer requirements and equipment a color up mode is suitable for small batch of generic pieces of plastic in the process of product development, the structure is mixed and disorderly, uniform wall thickness, satisfied certain function requirements of small batch sample produce generic.

Vacuum injection mold, namely vacuum complex mold, also known as silica gel complex mold, needs to be used in silica gel mold. Both under the condition of vacuum deaeration of castable, mixing, preheating, note type, and in constant temperature box 60 ℃, 80 ℃ for 2 to 3 hours of secondary curing process, silicon complex mode of imitation, to reach the strength and hardness of the raw materials such as ABS, can also according to customer requirements and equipment a color up mode is suitable for small batch of generic pieces of plastic in the process of product development, the structure is mixed and disorderly, uniform wall thickness, satisfied certain function requirements of small batch sample produce generic.

What are the advantages of simple injection mold forming?

1. No deformation or shrinkage of silica gel mold; High temperature resistant, mould can be used repeatedly after forming; Provide convenience for product imitation;

2. Silicone molds are cheap, with short manufacturing cycle, which can prevent unnecessary loss before mold opening.

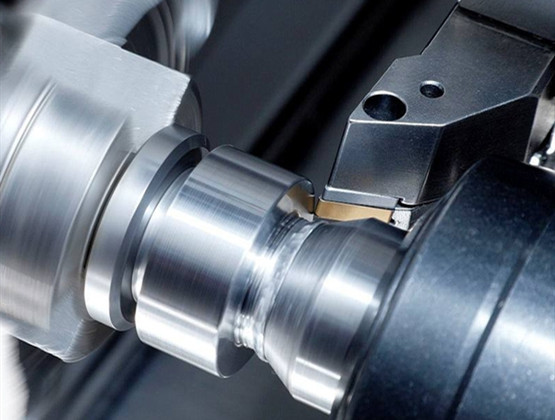

Numerical control processing technology

Production CNC machining

Do I need to produce the processing parts? For quantities greater than 15, we offer competitive prices, as well as first piece inspection (FAI) reports, material certification and other finishing options (such as anodizing and chromate plating). learn more

Threading options and guidelines

For machined parts, you can easily add thread features, including keys and coil plugins. These can be specified in your interactive quote. After the quote is returned, the 3D display will show the type of thread that each feature might use. You can select a different thread (if possible) or no thread at all functionally.learn more

Why simple injection mold molding in Mingren

The way of cooperation is flexible

Be able to quickly respond to market dynamics and provide parts according to market demand to simplify your supply chain

Mass customization of product lines

Rapidly iterating part design and accelerating product development in response to market demand.

The time cycle is guaranteed

Stable production line to ensure product quality and production cycle

Cancel the minimum order

There is no minimum order quantity, which reduces the inventory cost and storage cost.

Material selection

We stock more than 30 kinds of engineering grade plastics and metal materials for various parts applications and industries. Materials range from plastics such as ABS, polycarbonate, nylon and PEEK to aluminum, stainless steel, magnesium and copper.